At this municipal water district just outside of Portland, Oregon, I provide 30,000 members of the public with potable water and wastewater engineering services. Primarily I manage large capital projects, leading public solicitations for consultants and contractors, and making sure their work gets completed to a high level of quality. I manage all the major improvements to our wastewater treatment plant, aiming for reliable sewage treatment with less energy input. I am often the person the district calls upon to respond to big emergencies that demand outside resources and contracts quickly, and in calmer times I work proactively to get ahead of problems. My planning style uses simple, visual, and comprehensive communicating to bring technical and non-technical stakeholders onto the same page. GIS mapping and CAD software are tools I put to use frequently to generate summaries of complex information, making the problem at hand intuitive to understand for everyone.

The capital projects at our wastewater treatment plant appeal to my desire to analyze, understand, diagnose, and repair complex systems. I take the time to survey and map exactly how our plant combines mechanical equipment, tanks, and microbes to digest pollutants out of wastewater. I coordinate with day-to-day plant operators, managers, Energy Trust of Oregon, and consulting engineers to forge more reliable and energy efficient schemes to treat the incoming sewage.

My approach for one project in particular started by listening closely to the day-to-day issues faced by plant operators. Their descriptions guided my next steps in data collection and analysis of historical data and plant records. Rerouting and redrawing Process and Instrumentation Diagrams revealed an opportunity to treat the same amount of waste activated sewage sludge using fewer facilities and far less electricity. The new concept cost sever hundred thousand dollars less than previously budgeted tasks, so I successfully lobbied to change the course of the annual budget, and got the new project executed. With a sound concept in hand, I hired on consulting engineers to detail the project, and publicly solicited bids from contractors to construct the new works. At the end of 2021, the project is installed and the long-term process of switching over sludge treatment operations is underway.

This systemic restructuring, both from the above-mentioned project and other projects, is bringing about significant reductions in labor input, environmental risk, operating cost, and energy demand. Treating wastewater demands a vast flow of electric power to keep the downstream Willamette River clean – on average running at 382,000 watts at any given time. The projects I manage are expected to eventually reduce this power demand by tens of thousands of watts, mostly by cutting back on the mass of air blown into aeration basins and aerobic digesters. The energy savings is comparable to the energy consumed by dozens of households.

Outside of the plant, I also work on the potable water delivery system supplying water to people’s homes, and on the sanitary sewer network draining flushed toilets to the treatment plant. At the start of 2022, my biggest focus is on modernizing several wastewater lift stations and sewer trunk mains, initially built during the 1960’s.

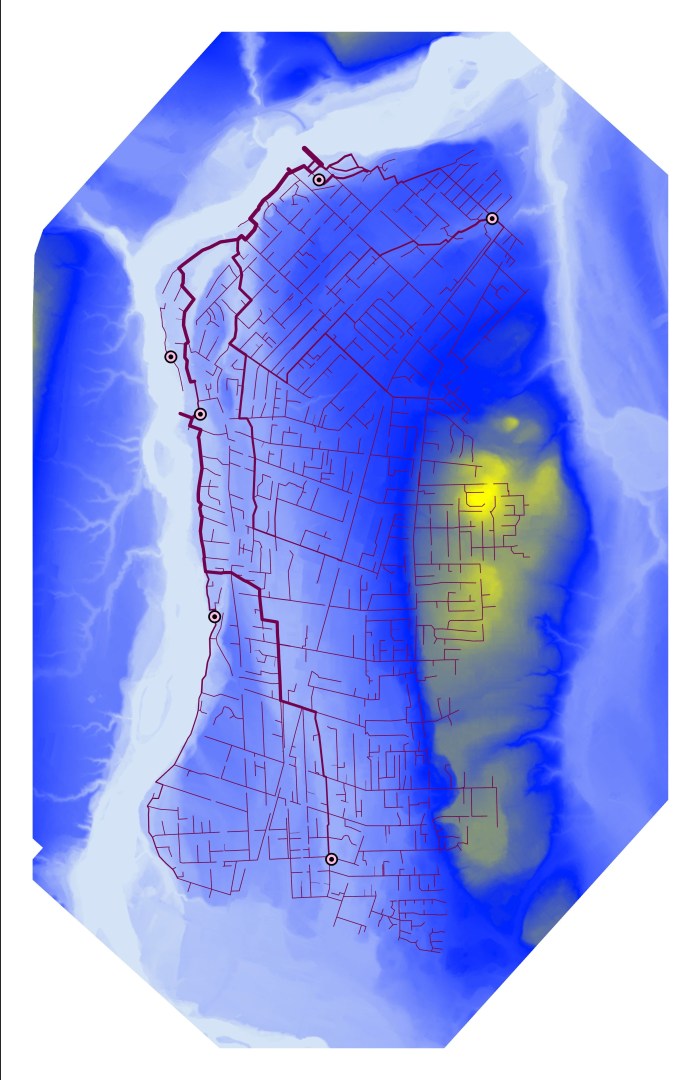

The map below, for instance, seeks to visually show how a carefully laid network of pipes, all laid out to follow the topography of the land, eventually create a nearly organic form as small flows of wastewater gather into large underground streams flowing downhill to be treated. Pink dots represent lift stations where the wastewater requires a boost along the way to keep the flow clear of the Willamette River.

On a project to improve our drinking water infrastructure, I created a GIS tools to streamline the work. The District tasked me with getting 6,000 aging water meters of varying makes and models replaced with one standardized type. Early on, I recognized the primary risk involved in this project: keeping the records straight on which of the 6,000 meters had been replaced, making sure all customers were billed correctly for the water they used, regardless of which meter it flowed through, and identifying the outliers that would required extra resources from District staff. So in addition to procuring the new meters through one contract and soliciting an installation Contractor through a separate bid solicitation, I further developed an interactive GIS database and mobile map to guide bookkeeping, and brought everyone up to speed on how to use it.

From their own smart phone in the field, our external contractor had a map of which set of meters to install next, and had a means to flag meters in need of specific attention. Through the same GIS tool, District utility workers followed in their wake and repaired the water services in need of extra attention. The GIS tool was a great success and made it easy to keep work well organized through the year-long, $1 million project. The old water meter below was one of those flagged through the GIS tool as needing a little extra attention.