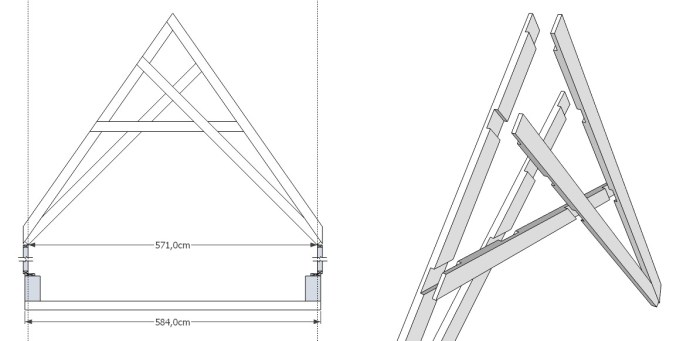

In the scarcely populated woods of Eastern Norway, I learned, hands-on, how to build while crafting a modern take of a traditional stave church unique to medieval Norway. Through the first year of construction while I was there, we formed the foundation and raised the 50-foot tall weatherproofed core of the church. Practical skills gained from this work compliment my theoretical strength, giving deeper understanding of my engineering work. My favorite tasks wove together the fibers of 3,500 lbs of spruce into the five massive trusses that support the choir roof. In addition to survey and design, I constructed the trusses and raised them into place.

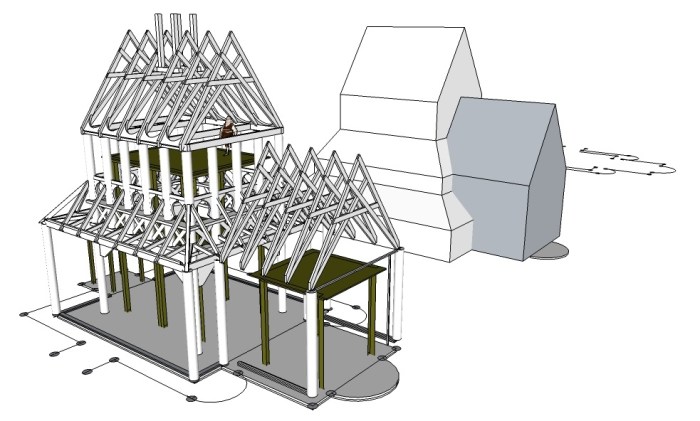

I lived and worked at Lia Gaard in a scarcely populated corner of Norway for nearly a year building the 19 meter (62 ft) tall replica of a traditional Norwegian “stave church” shown, partly constructed, in the picture below. Norway’s oldest stave churches date back to the 11th century AD and are today among the foremost symbol of Norway’s wood-built heritage.

Our take on the classic design employs a custom timber frame as the structural core, while modern insulation in the outer walls allow the church to be heated, even when winter temperatures annually drop to -20 deg C (-4 deg F).

A fun task as we moved forward constructing the core was designing details for the next steps. My background in engineering and CAD modeling came in handy. I would frequently measure, design, and model components with SketchUp before finally cutting and joining the elements. This process of measure-design-build-repeat gave new dimension to my construction experience up until this point, previously focused on computer-aided design and high-level management.

The roof trusses pictured in the series below span 5.7 meters (19 ft) and weigh 320 kg (700 lbs) each.

I worked first and foremost as a carpenter, which provided me with a wealth of hands-on experience with construction. We poured the foundation at the end of June 2014. By the time I left the project in April 2015, we had raised the entire skeleton, weather-proofed the outer shell and done a fair amount of work on the interior.

Construction continued for two years after I left, and on midsummer night’s eve 2017, exactly three years after we started work, I returned to celebrate the inauguration.