At a private small hydropower development firm, I co-managed the construction of two new run-of-the-river hydropower plants in Southern Norway, adding 3,100 kW of renewable capacity to the grid. In my central role, I coordinated all equipment supplier, consulting engineers, and contractors to bring the twin $8 million plants online. I reviewed and approved every invoice, contract, and construction drawing for the entire project, and wrote the social and environmental pre-construction plans for public review and government approval.

Norway recently incentivized the development of new “small” (1 MW to 5.5 MW) run-of-the-river plants. These plants can be built with a lighter impact to the environment when careful design is employed.

Most of my work was managing the construction of such new plants. I managed budgets, timelines, and contracts intensively for the first time in my career.

Before construction of a new hydrpower plant may begin, one type of environmental plan (“detaljplan”) serves as both the pre-design for the power plant as well as a permitting document. I wrote several of these, two of which were accepted. Writing the “detaljplans” required several site visits and conceptual layouts of the intake sites, powerstation site, and penstock alignments. I drew maps, calculated energy production potential, and 3D-modeled concepts for various intake structure, both with and without dams.

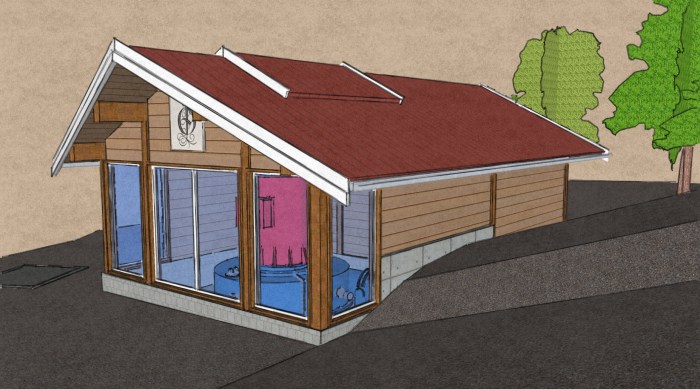

Two plans, accepted by the Norwegian regulatory authority, lead to the detailed design and construction of the power station under construction in the image below. Completed in 2014, this station houses two pelton turbines anchored to the massive reinforced concrete foundation shown in the picture. The pair of blue 700 mm diameter pipes in the background are hydraulically independent, conveying water from two separate tributaries, each over a kilometer away, roughly 200 meters higher in elevation.

In addition to overseeing these twin projects through construction, I developed concepts for power stations in earlier pre-construction phases of planning. I enjoyed these tasks as they allowed me the creativity to explore new concepts and exposed me to fields outside of engineering, such as private financing, hydrology, and architecture.

The concept for a single-turbine power station in the picture below allows the roof to be lifted off with a crane so the heavy generator can be hoisted out through the void for maintenance. The economical structure spares the cost of a permanent pulley system and remains respectful of the architectural aesthetic of this part of rural Norway. Modified and refined versions of the concept were eventually used at other hydropower stations.

Another common task was to visit a potential site and developed a rough feasibility concept for a full power plant with all its components. I put together cost estimates and hydraulic calculations to assess a new project’s annual energy generation against its capital cost. Maps and other big-picture communication were always required when we moved forward to submit formal applications for development.

Where the dam (or dam-less intake structure) or penstock would be constructed within the vicinity of inhabited areas, I would conduct the calculations to assess the dam’s and pipeline’s safety class. In the image below, I visualized a proprietary intake structure at the top edge of steep rapids. Such an intake would blend in with the topography and allow both debris and aquatic life to pass over the intake. This intake design would avoid a high safety risk in the event of failure by not impounding water in the river. The penstock, however, would be placed in a higher safety class.

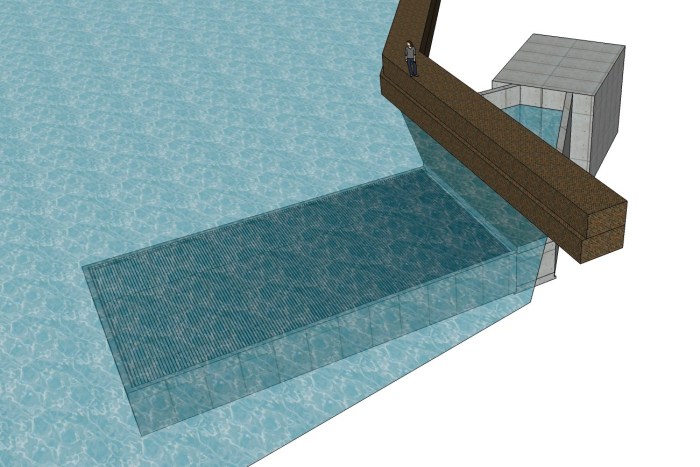

My favorite concept I worked on, pictured in the two images below, was designed from scratch to be built in an environmentally sensitive area. It avoids a dam altogether, and would put in a 999 kW propeller turbine off-stream. Even when running at full speed for most of the year, such a turbine would only divert a small portion of the river’s total flow.

This river is sensitive habitat for a migrating species of eel, so constructing a dam to control the river was environmentally unacceptable, and costly. This concept instead takes advantage of a naturally occurring pool in the river to draw water through a submerged intake. This intake would be virtually hidden once constructed.

The most unorthodox component of this project involves hand building a deteriorating stone wall historically used for centuries to keep timbers in line as they were floated to saw mills down river. By connecting the new stone wall to the remains of the eroding stone wall, and extending the new wall up along the stream bank, the power plant proposed in this concept would literally tie in to and protect the industrial legacy of the region. This hydropower development would thereby protect an endangered eel, provide funding for historical preservation, and produce renewable energy, all in a cost-effective way.